Products

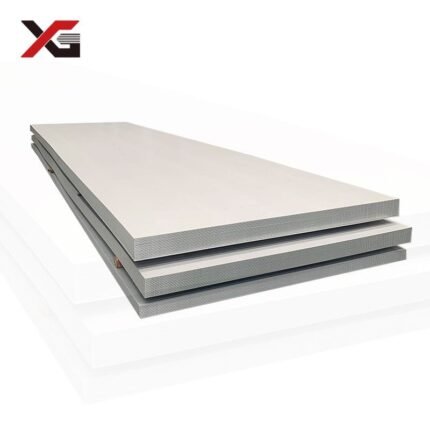

Stainless steel sheet

Stainless steel is initially produced in slabs, which are then put through a conversion process using a Z mill, which converts the slab into coil prior to further rolling. These wide coils are typically made at around 1250mm (sometimes a little wider) and are known as ‘mill edge coils’. After the stainless steel roll is rolled flat, it becomes a stainless steel sheet(plate).

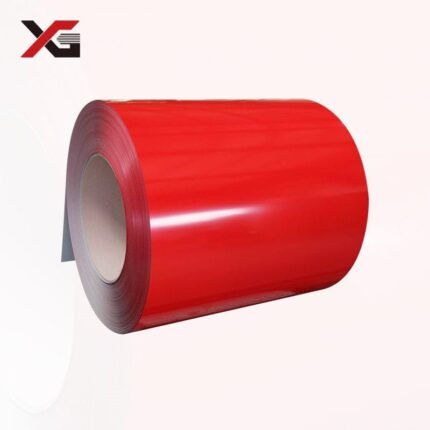

Color coated coil

Color-coated coils use hot-dip galvanized sheets, hot-dip galvalume sheets, electro-galvanized sheets, etc. as substrates. After surface pretreatment (chemical degreasing and chemical conversion treatment), one or several layers of organic coatings are coated on the surface, and then A product that is baked and solidified. Colored steel coils are named after being coated with organic coatings of various colors, referred to as color-coated coils.

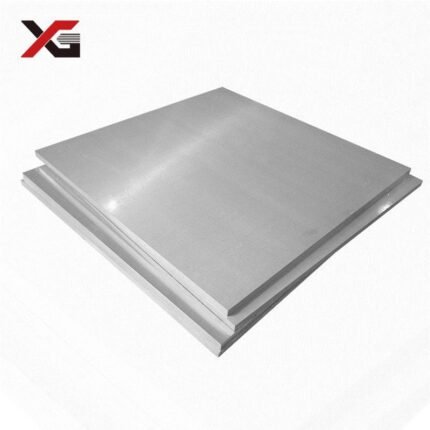

Carbon steel sheet / plate

Carbon steel plate is a rectangular plate made of non-alloy material mainly composed of iron and carbon. In addition to carbon, it also contains a small amount of silicon, manganese, sulfur, phosphorus and other elements. The higher the carbon content, the better the hardness and the better the strength. Due to its good mechanical properties and plasticity, it is widely used in various fields.

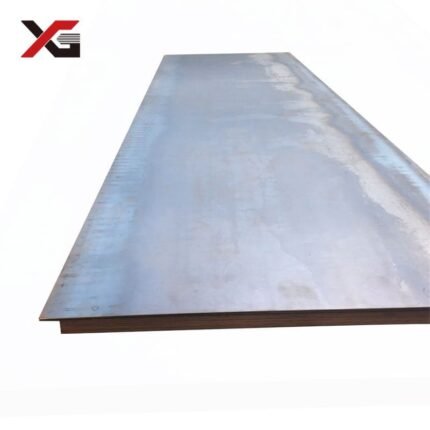

Galvanized coil

Galvanized coils are materials produced through a continuous hot-dip galvanizing process using hot-rolled steel strips or cold-rolled steel strips as the base plate. Hot-dip galvanized sheets are supplied as rectangular flat sheets after cross-cutting; hot-dip galvanized coils are supplied as rolls after being rolled. Their main characteristics are: strong corrosion resistance, good surface quality, conducive to deep processing, economical and practical, etc.

Carbon steel coil

Carbon steel coil is a commonly used metal material with extensive applications in many fields. It has good mechanical and processing properties and is widely used in fields such as automobile manufacturing, shipbuilding, construction, and bridges.

Boiler vessel plate

Boiler plate is a hot-rolled medium-thick plate material used to manufacture superheaters, main steam pipes and boiler firebox heating surfaces. Since the boiler steel plate works under medium temperature (below 350oC) and high pressure, in addition to bearing high pressure, it is also subject to impact, fatigue load and water and gas corrosion. The performance requirements for boiler steel are mainly good welding and cold bending properties. Certain high temperature strength and resistance to alkali corrosion, oxidation, etc.

Carbon steel round seamless pipe

Carbon steel pipes are pipes made of carbon steel. They are one of the most commonly used metal materials and have good mechanical properties, processing properties and corrosion resistance. According to the production method, it can be divided into two types: seamless steel pipe and welded steel pipe.

Pre-Painted Galvanized

Galvanized coils are materials produced through a continuous hot-dip galvanizing process using hot-rolled steel strips or cold-rolled steel strips as the base plate. Hot-dip galvanized sheets are supplied as rectangular flat sheets after cross-cutting; hot-dip galvanized coils are supplied as rolls after being rolled.

Their main characteristics are: strong corrosion resistance, good surface quality, conducive to deep processing, economical and practical, etc.